Sign Up For Our Off Grid Newsletter

Testimonials

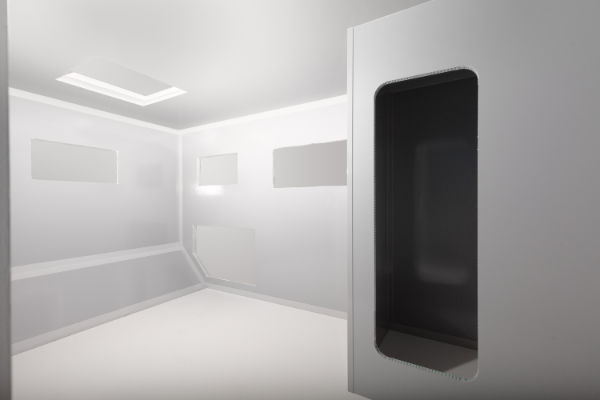

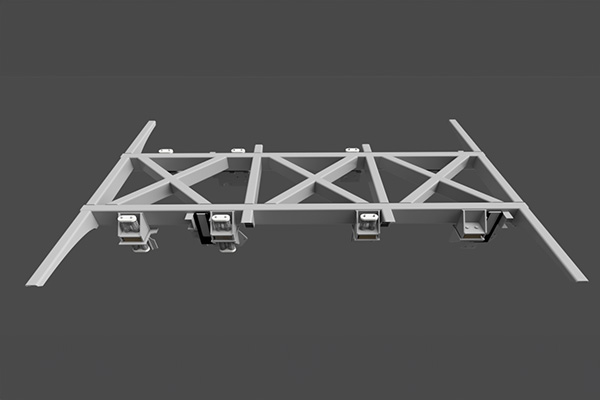

The team at Off Grid Customs assembled and mounted a 15′ Total Composites custom habitat shell onto my fuso 4×4 truck. I am now in the process of fitting it out for my future journeys. They did a really good job on it and I would be happy to use their services again for any kind of camper build work that I could not do myself.

The folks at OGC are experts in what they do, and it’s been well worth the investment knowing that my camper and all the features inside/outside it are very well made. Even in the hot desert, my dog and I can be comfortable inside the camper with the windows open and fan running.

The crew at Off Grid Customs is friendly & helpful. They picked up my truck camper shell and I cannot be happier with the quality of their work.

We’ve already put over 5,000 km on the truck with the new camper shell, including driving through the Rocky Mountains in the winter. The entire camper shell and the optional items are rock solid. It’s amazing how warm the camper is in the winter.

Awesome and professional service! Loved working with Allan and everyone there. I would recommend them to anyone wanting the best craftsmanship around!

Hours: 8 am – 4:30 pm

Sat-Sun: Closed

Scheduled appointments only – No walk ins

Contact

1101 Commercial Pl, Squamish, BC

Office: 604-390-2100